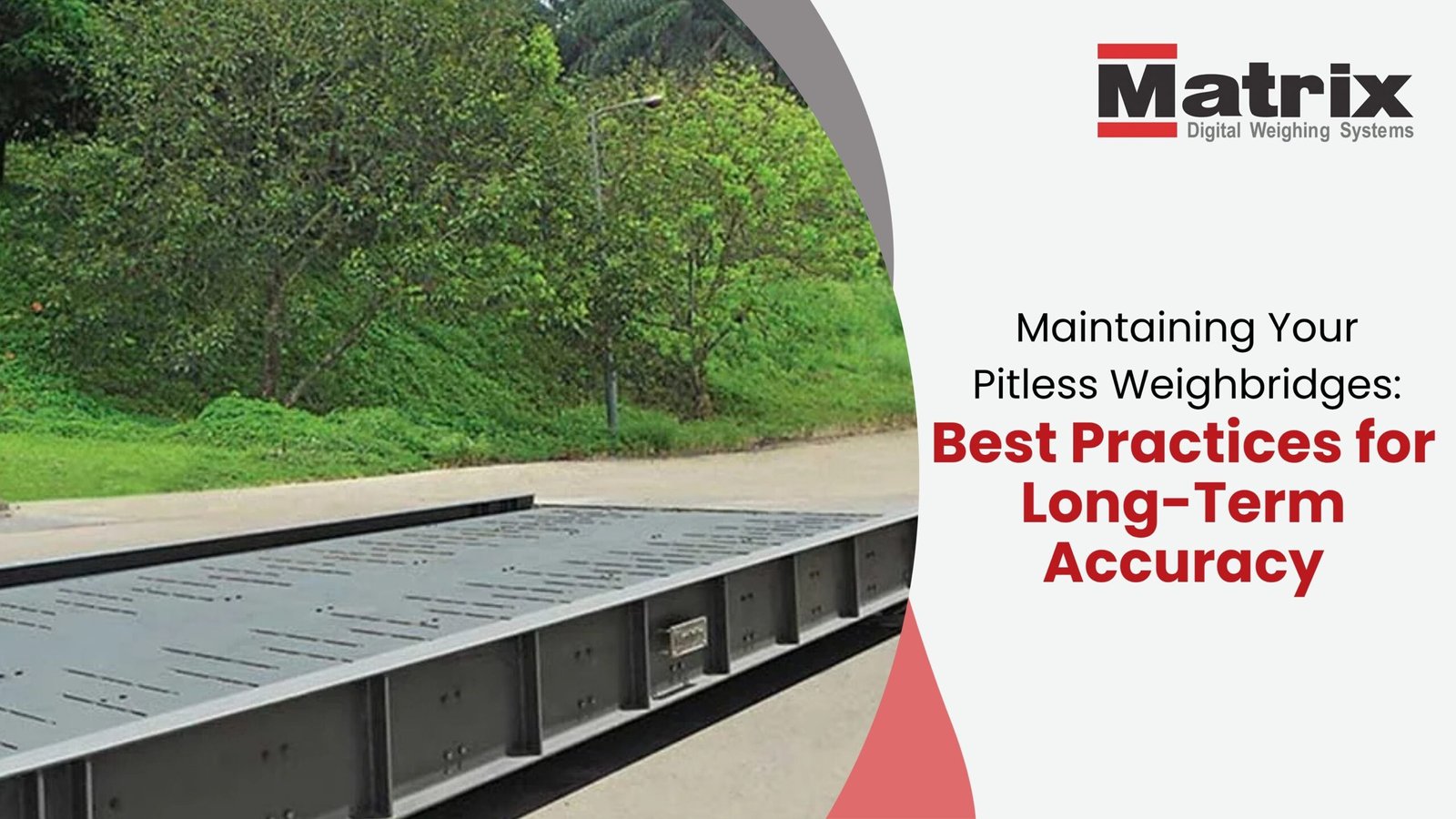

Maintaining Your Pitless Weighbridges: Best Practices for Long-Term Accuracy

Most weighbridge failures stem from neglected maintenance rather than equipment defects. A weighbridge operating without regular cleaning and calibration drifts in accuracy by 2-5% within six months, translating to thousands of dollars in measurement errors for high-volume operations. Consistent maintenance routines protect measurement precision, extend equipment lifespan, and ensure regulatory compliance.

This guide covers daily cleaning, weekly inspection, monthly maintenance, calibration, environmental protection, training, troubleshooting, and technology integration to ensure long-term accuracy and prevent downtime.

Daily Maintenance Tasks

Cleaning Platform Surface and Removing Debris

Start each day with a visual sweep of the weighing platform. Remove loose debris, accumulated dirt, and any objects that affect load distribution across the surface.

Pay attention to approach ramps where mud and gravel accumulate. These materials transfer onto the platform and create false readings when trapped under vehicle tires.

Visual Inspection of Load Cells and Junction Boxes

Check load cell housings for visible damage, moisture accumulation, or cable wear. Look for rust spots, especially around seals where water penetrates protective coatings.youtube

Junction boxes should remain dry and sealed. Water intrusion causes electrical failures and erratic weight readings that compromise measurement accuracy.

Checking for Water Accumulation and Clearing Drainage

Even pitless weighbridges need drainage attention. Water pools around foundations and underneath platforms create corrosion problems over time.

Ensure drainage channels remain clear of debris. Blocked drainage leads to standing water that accelerates metal deterioration and damages electronic components.

Weekly Maintenance Routine

Detailed Inspection of Platform and Structural Components

Conduct thorough platform inspections looking for cracks, warping, or structural movement. Steel platforms show stress through visible flexing or paint cracks.

Check mounting bolts and connection points for looseness. Vibration from repeated vehicle traffic gradually loosens fasteners, affecting platform stability and measurement consistency.

Conducting End-Middle-End Weight Tests

Place a known weight on three positions: front end, center, and rear end of the platform. Record all three readings.

Readings should match within 0.5% across all positions. Larger variations indicate load cell problems or structural issues requiring immediate attention.

Removing Dirt and Debris from Underneath the Platform

Access the underside of the platform to clear accumulated material. Dirt buildup between the platform and foundation creates binding that affects weighing accuracy.

Use compressed air or soft brushes to clean around load cells without direct impact. High-pressure washing damages sensitive components and forces water into sealed housings.

Monthly Maintenance Checks

Checking for Structural Damage and Platform Movement

Inspect foundation edges for damage to side frames and end frames. Settlement or ground movement causes misalignment that throws off calibration.

Measure platform clearances at multiple points. Changes from baseline measurements indicate structural shifts requiring professional assessment.

Jet or Air Cleaning of Platform and Components

Monthly deep cleaning removes stubborn buildup that daily maintenance misses. Use jet washers to clean the platform thoroughly while avoiding direct contact with load cells and junction boxes.

Let the system dry completely before resuming operations. Moisture affects electrical resistance in load cells and creates temporary measurement errors.

Rebalancing (Zeroing) the Weighbridge and Test Comparisons

After cleaning, zero the weighbridge and repeat the end-middle-end test. Compare post-cleaning results with pre-cleaning readings.

Significant discrepancies between the two test sets indicate debris buildup affected previous accuracy. Document these findings to establish cleaning effectiveness.

Annual or Periodic Calibration

Importance of Calibration for Legal and Operational Accuracy

Calibration maintains accuracy within legal tolerances required for commercial transactions. Many jurisdictions mandate annual calibration for weighbridges used in trade.

High-traffic operations need calibration every six months rather than annually. Weighbridges processing 100+ vehicles daily experience faster drift than low-volume systems.

Calibration Procedures and Documentation

Professional calibration involves four key tests: zero point with no load, working range verification using certified weights, linearity testing during loading and unloading cycles, and eccentric error checks at platform corners.

Technicians document all readings, adjustments made, and final calibration results. These records prove compliance during audits and establish calibration history for predictive maintenance.

Compliance with Industry Standards and Regulations

Calibration must follow established industry standards using certified reference weights. Weighbridges operating under legal metrology require stamps and certificates from authorized agencies.

Maintain comprehensive calibration logs including dates, technician credentials, weight standards used, and adjustment details. These records become critical during regulatory inspections.

Environmental and Site Considerations

Weather Protection Measures for Load Cells and Electronics

Load cells with IP68 or IP69K ratings resist moisture better than standard models, but protective covers add extra insurance against monsoon conditions.

Install weather shields over junction boxes and cable entry points. Water intrusion through damaged seals causes the majority of electronic failures in outdoor weighbridges.

Managing Drainage and Preventing Waterlogging

Grade the area around pitless weighbridges to direct runoff away from the foundation. Standing water under the platform creates humidity that corrodes load cells and mounting hardware.

Preventing Rust and Corrosion on Metal Components

Apply rust-inhibiting coatings to exposed metal surfaces annually. Steel platforms in humid or coastal environments corrode faster than those in dry climates.youtube

Replace damaged paint immediately to prevent rust from spreading. Small rust spots expand rapidly once moisture penetrates protective coatings.youtube

Operator Training and Best Use Practices

Proper Vehicle Positioning on the Platform

Train operators to center vehicles on the platform with all axles fully on the weighing surface. Partial positioning creates eccentric loads that reduce accuracy.

Require drivers to stop completely before weight capture. Rolling measurements introduce dynamic forces that affect readings.

Avoiding Overloading and Incorrect Loading

Enforce strict capacity limits. Overloading damages load cells through metal fatigue even when the platform doesn’t show visible damage.

Single-axle overloading causes problems too. When one axle exceeds its proportional load capacity, that load cell experiences premature wear.

Reporting and Addressing Anomalies Promptly

Establish clear protocols for reporting unusual readings or system behavior. Early detection prevents small problems from becoming expensive failures.

Investigate any reading that deviates more than 1% from expected values. Drift happens gradually, but sudden changes indicate component failure or structural issues.

Troubleshooting Common Issues

Identifying Load Cell Faults and Errors

Perform zero balance tests to detect load cell damage from overload, shock load, or metal fatigue. Load cell shift during this test reveals physical damage requiring replacement.youtube

Bridge resistance tests identify damaged resistors inside load cells. Test each leg individually since paired resistors often fail simultaneously and mask each other’s problems.youtube

Handling Environmental Damage or Mechanical Wear

Check cables for cuts, crimps, or abrasions that expose strain gauges to water and chemicals. Cable damage causes irregular readings before complete load cell failure.

Resistance-to-ground testing determines if electrical current leaks to the load cell body. This leakage creates measurement inconsistencies that appear intermittently.youtube

When to Call Professional Maintenance Services

Contact specialists when readings drift despite cleaning and zeroing. Persistent accuracy problems require load cell replacement or platform structural repair.

Electrical issues beyond basic cable inspection need professional diagnosis. Modern weighbridge electronics contain complex circuitry that requires specialized testing equipment.

Leveraging Technology for Maintenance

Using Diagnostic Software and Remote Monitoring

Modern weighbridges include diagnostic capabilities that flag load cell drift, voltage irregularities, and calibration needs before failures occur.

Remote monitoring systems track usage patterns and environmental conditions. This data helps predict maintenance needs based on actual operating stress rather than arbitrary time intervals.

Automating Alerts for Calibration and Maintenance

Configure automatic alerts when the system detects readings outside normal variance. Immediate notification prevents continued operation with compromised accuracy.

Schedule-based reminders ensure routine maintenance doesn’t get overlooked during busy periods. Digital maintenance logs track completion and flag overdue tasks.

Data Analytics for Predictive Maintenance

Analyze historical performance data to identify patterns preceding failures. This predictive approach reduces unplanned downtime by 40-60% compared to reactive maintenance.

Track calibration drift rates to optimize service intervals. Some weighbridges need quarterly attention while others maintain accuracy for 12-18 months.

Frequently Asked Questions

How often should I calibrate my pitless weighbridge?

Annual calibration meets minimum requirements for most applications. High-traffic operations (100+ vehicles daily) should calibrate every six months to maintain accuracy. Legal metrology applications may require more frequent verification depending on local regulations.

Can I perform calibration myself or do I need a certified technician?

Professional calibration requires certified technicians using traceable reference weights. DIY calibration lacks legal validity and won’t satisfy regulatory requirements for commercial weighing operations. Only qualified technicians can issue calibration certificates.

What causes load cells to fail prematurely?

Overloading creates the most load cell damage through metal fatigue. Moisture intrusion from damaged seals ranks second. Shock loads from vehicles driving onto the platform too fast also contribute to early failure. Proper operating procedures extend load cell life by 3-5 years.

How do I know if my weighbridge readings are accurate between calibrations?

Conduct weekly end-middle-end tests using the same known weight. Record results and track trends over time. Readings drifting more than 0.5% from baseline indicate accuracy degradation requiring investigation.

What maintenance tasks can operators handle versus requiring professional service?

Operators manage daily cleaning, visual inspections, debris removal, and basic end-middle-end testing. Professional service handles calibration, load cell replacement, structural repairs, and electrical diagnostics. Attempting complex repairs without proper training often causes additional damage.

Protect Your Investment Through Consistent Maintenance

Weighbridge accuracy depends on systematic maintenance covering daily cleaning, weekly inspections, monthly deep maintenance, and annual calibration. These practices prevent measurement drift, extend component life, and maintain regulatory compliance.

Don’t wait for failures to force expensive emergency repairs. Implement these routines now to protect measurement accuracy and operational continuity.

Matrix Weighbridge provides comprehensive maintenance support for pitless weighbridge systems across Indian industrial facilities. Our service programs include scheduled calibration using certified reference weights, preventive maintenance inspections, load cell diagnostics, and emergency repair services.

We offer customized maintenance contracts tailored to your traffic volume and operational requirements. Our technicians document all service activities to maintain compliance with legal metrology standards and provide detailed accuracy reports after each calibration.

Schedule your weighbridge maintenance inspection today. Contact Matrix Weighbridge for a complete system assessment and customized maintenance plan that keeps your weighing operations accurate and compliant. Visit matrixweighbridge.com or call our service team to book your appointment now.