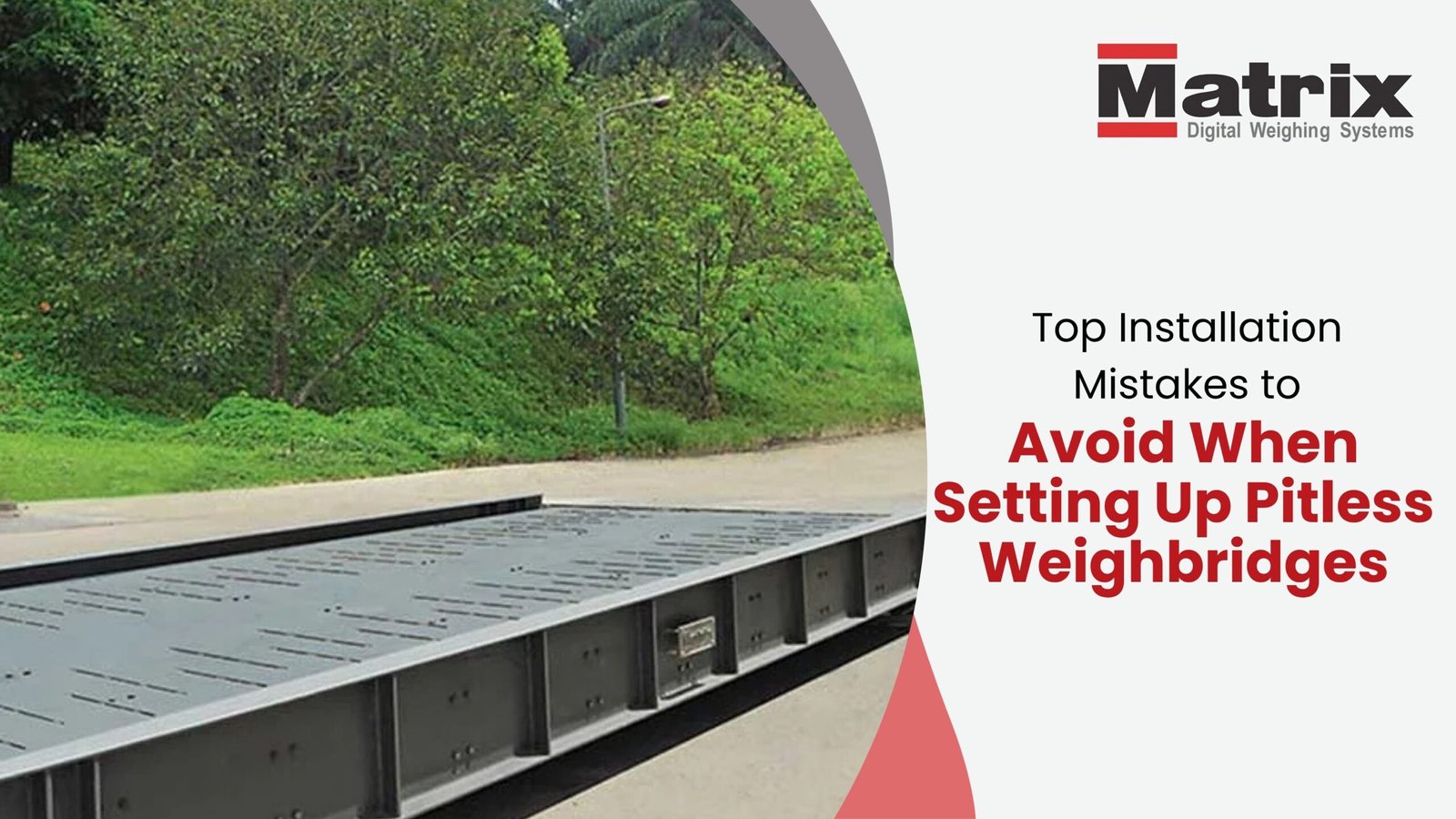

Top Installation Mistakes to Avoid When Setting Up Pitless Weighbridges

Introduction

A poorly installed pitless weighbridge costs you thousands in repairs, recalibration, and operational downtime within the first year. Installation errors create cascading failures—foundation settling shifts load cells, misaligned platforms produce inconsistent readings, and inadequate drainage corrodes electrical components. Most businesses discover these problems only after operations begin, when fixing them requires disassembly and reconstruction.

This guide identifies nine critical installation mistakes that compromise accuracy, durability, and safety, showing you exactly what goes wrong during site preparation, foundation work, load cell mounting, electrical setup, and commissioning so you can avoid expensive failures before they happen.

Mistake 1: Inadequate Site Preparation

Poor Soil Compaction and Foundation Risks

Soil must be compacted to specific bearing pressure standards before foundation work begins. Loose or improperly compacted soil settles unevenly under the weighbridge’s weight, causing platform misalignment and load cell damage.

This settlement happens gradually over months. By the time you notice accuracy problems, the foundation has shifted enough to require expensive structural repairs.

Ignoring Ground Stability Assessment

Rocky terrain, high water tables, and underground utilities affect foundation design. Sites with poor drainage or unstable soil conditions need reinforced foundations with deeper footings and enhanced drainage systems.

Skipping geotechnical assessment leads to foundation designs that fail under actual site conditions, particularly during monsoon seasons when water infiltration destabilizes soil.

Mistake 2: Incorrect Foundation Design and Execution

Failing to Meet Strict Tolerance Requirements

Here’s the uncomfortable truth: weighbridge foundations require tolerances within 5mm. Regular construction tolerances don’t work. Even minor deviations affect load distribution and measurement accuracy.

This precision demands specialized surveying equipment and experienced civil contractors. General construction teams often lack the expertise to achieve weighbridge-grade tolerances.

Insufficient Concrete Curing Time

Contractors rush commissioning by loading the weighbridge before concrete reaches full strength. Concrete needs 21-28 days to cure properly. Premature loading creates micro-fractures that compromise structural integrity.

These fractures widen under repeated heavy vehicle loads, eventually causing foundation cracking and platform misalignment.

Using Improper Reinforcement Materials

Foundation drawings specify exact reinforcement requirements based on soil conditions and load capacity. Substituting materials or reducing reinforcement to cut costs creates weak points that fail under sustained heavy loads.

Mistake 3: Misalignment of Platform and Load Cells

Load Cell Positioning Errors

Load cells must align precisely with structural support points. Misalignment creates uneven load distribution, causing some cells to bear more weight than others. This imbalance produces inaccurate readings and accelerates component wear.

The platform’s center line determines load cell placement. Setting out from the center outwards ensures symmetrical load distribution across all cells.

Improper Load Application

Load cells fail when loads apply at angles rather than vertically. Twisted loads, side forces, or binding against check-rods and bumpers transmit incorrect forces to sensors.

Installation teams must ensure the platform moves freely without binding against any fixed structure. Even slight contact with surrounding concrete or ramps introduces measurement errors.

Mistake 4: Improper Load Cell Installation and Calibration

Selecting Incompatible Load Cells

Load cell quality directly determines weighbridge accuracy. Low-grade sensors drift over time, requiring frequent recalibration. High-quality cells maintain accuracy for years despite environmental exposure.

Many installations fail because contractors choose load cells based on price rather than specifications matching the platform’s weight, capacity, and environmental conditions.

Skipping Multi-Stage Calibration

Calibration must occur at multiple capacity levels—empty platform, partial load, and maximum capacity. Single-point calibration produces accurate readings only at that specific weight.

Proper calibration uses certified test weights distributed across the platform to verify accuracy throughout the entire weighing range.

Mistake 5: Inadequate Electrical Protection and Wiring Practices

Failing to Protect Junction Boxes from Moisture

Junction boxes house sensitive electrical connections that corrode when exposed to water. Moisture-resistant enclosures with proper sealing prevent water infiltration during rains.

The uncomfortable reality: most electrical failures stem from water damage in junction boxes, not load cell malfunction. Proper sealing eliminates 80% of electrical maintenance issues.

Ignoring Cable Routing Standards

Load cell cables must run through PVC conduit buried at least 500mm below the surface. Cables routed above ground or through shallow trenches get damaged by traffic, temperature fluctuations, and physical impact.

Cables must maintain 450mm separation from power lines to prevent electrical interference that creates signal noise and measurement inconsistencies.

Neglecting Surge Protection

Lightning strikes and power surges destroy unprotected load cells and indicators. Surge protectors on power supply lines and signal cables prevent thousands in equipment replacement costs.

Mistake 6: Poor Ramp Construction and Vehicle Access Planning

Building Ramps with Incorrect Slopes

Ramps steeper than recommended gradients cause traction problems. Drive axles slip during wet conditions, and trailer anti-submarine bars scrape the ground when approaching steep ramps.

This creates safety hazards and vehicle damage while slowing operations as drivers navigate problematic ramp angles.

Inadequate Turning Circle Planning

Longer vehicles need wider turning circles to approach weighbridges without jackknifing or damaging ramps. The simplest verification: drive your largest vehicle through the planned route using traffic cones before finalizing ramp placement.

Sites with insufficient maneuvering space force vehicles into awkward angles that damage ramp edges and create bottlenecks during peak traffic.

Mistake 7: Neglecting Environmental and Weather Considerations

Poor Drainage Design

Water pooling around pitless weighbridges damages foundations and corrodes exposed metal components. Drainage systems must channel water away from the platform and prevent accumulation around load cell mounting points.

Natural drainage slopes work best, eliminating mechanical drainage systems that clog and require maintenance.

Ignoring Wind and Vibration Effects

Strong crosswinds exert lateral forces on elevated pitless platforms. These forces transmit to load cells, creating measurement errors during windy conditions.

Nearby machinery vibrations also register as additional weight. Installing vibration dampeners or relocating the weighbridge away from vibration sources prevents these interference errors.

Mistake 8: Insufficient Testing and Commissioning Procedures

Skipping Comprehensive Load Testing

Testing must include end-middle-end verification—placing test weights at different platform positions to confirm uniform load cell response. This identifies misaligned or faulty load cells before operations begin.

Many installations skip this step, discovering problems only when actual vehicles produce inconsistent readings.

Not Performing Regular Leveling Checks

Platforms shift slightly over time as foundations settle. Periodic leveling verification and recalibration maintain accuracy throughout the weighbridge’s lifespan.

Installations without scheduled leveling checks gradually lose accuracy, requiring expensive recalibration and structural adjustments.

Mistake 9: Lack of Training for Operators and Maintenance Staff

Underestimating Operational Knowledge Requirements

Operators must understand proper vehicle positioning, zero setting procedures, and basic troubleshooting. Untrained operators create measurement errors through improper weighing procedures.

Neglecting Maintenance Training

Maintenance staff need specific training on load cell inspection, junction box cleaning, and calibration verification. Generic maintenance knowledge doesn’t translate to weighbridge-specific requirements.

Regular inspections every six months prevent minor issues from becoming major failures.

Frequently Asked Questions

How long should I wait after foundation pouring before loading the weighbridge?

Wait 21-28 days for concrete to reach full curing strength. Loading earlier creates micro-fractures that compromise structural integrity and reduce platform lifespan. Plan installation timelines to accommodate this curing period without rushing commissioning.

Can I use general construction contractors for weighbridge installation?

No. Weighbridge foundations require 5mm tolerances—far stricter than regular construction standards. General contractors lack the specialized equipment and expertise to achieve these precision requirements. Use contractors experienced specifically in weighbridge installation.

What causes most weighbridge accuracy problems after installation?

Foundation settling and load cell misalignment cause approximately 60% of accuracy issues. Water damage to junction boxes accounts for another 20%. Proper site preparation, precise load cell positioning, and waterproof electrical protection prevent most post-installation problems.

How often should newly installed weighbridges be recalibrated?

Perform initial calibration immediately after installation, then again after two weeks of operation to account for minor settling. After that, calibrate every six months or per regulatory requirements. More frequent calibration during the first year catches installation-related issues early.

Do pitless weighbridges need different installation procedures than pit types?

Yes. Pitless systems require elevated foundation construction and precise ramp integration. They need more attention to vehicle approach angles and ramp slope calculations. However, they skip excavation and drainage complications that plague pit-type installations.

Conclusion

Installation quality determines whether your weighbridge delivers decades of accurate service or requires constant repairs and recalibration. The nine mistakes outlined here—from inadequate site preparation to insufficient training—create preventable failures that cost far more to fix after commissioning than to avoid during installation. Prioritize precision foundation work, proper load cell alignment, comprehensive electrical protection, and thorough testing.

Contact us today for expert weighbridge installation that eliminates these common mistakes from the start.

Matrix Weighbridge specializes in precision pitless weighbridge installation across India, handling everything from geotechnical site assessment to final calibration and operator training. Our installation teams achieve the strict 5mm foundation tolerances that ensure long-term accuracy, while our electrical protection systems prevent the moisture damage and signal interference that plague poorly installed systems. We use only certified load cells properly aligned and calibrated at multiple capacity levels, and we build ramps with correct gradients that accommodate your largest vehicles safely. Every installation includes comprehensive commissioning tests, detailed documentation, and operator training to maximize your weighbridge’s accuracy and lifespan. Visit matrixweighbridge.com or call us for a site evaluation and installation proposal that addresses your specific soil conditions, traffic patterns, and operational requirements.