MWS_Admin

December 11, 2025

Introduction Pit-type weighbridges save space but hide their vulnerabilities underground. Water accumulation damages load cells during monsoon seasons, debris clogs drainage channels, and corrosion spreads unnoticed […]

December 11, 2025

Mining operations and construction projects face a persistent challenge: weighing heavy equipment and materials at sites that exist for months rather than years. Installing permanent weighbridges […]

December 4, 2025

Introduction Urban logistics yards and industrial facilities face a common constraint: every square meter matters. Traditional above-ground weighbridges consume valuable space with approach ramps that extend […]

December 4, 2025

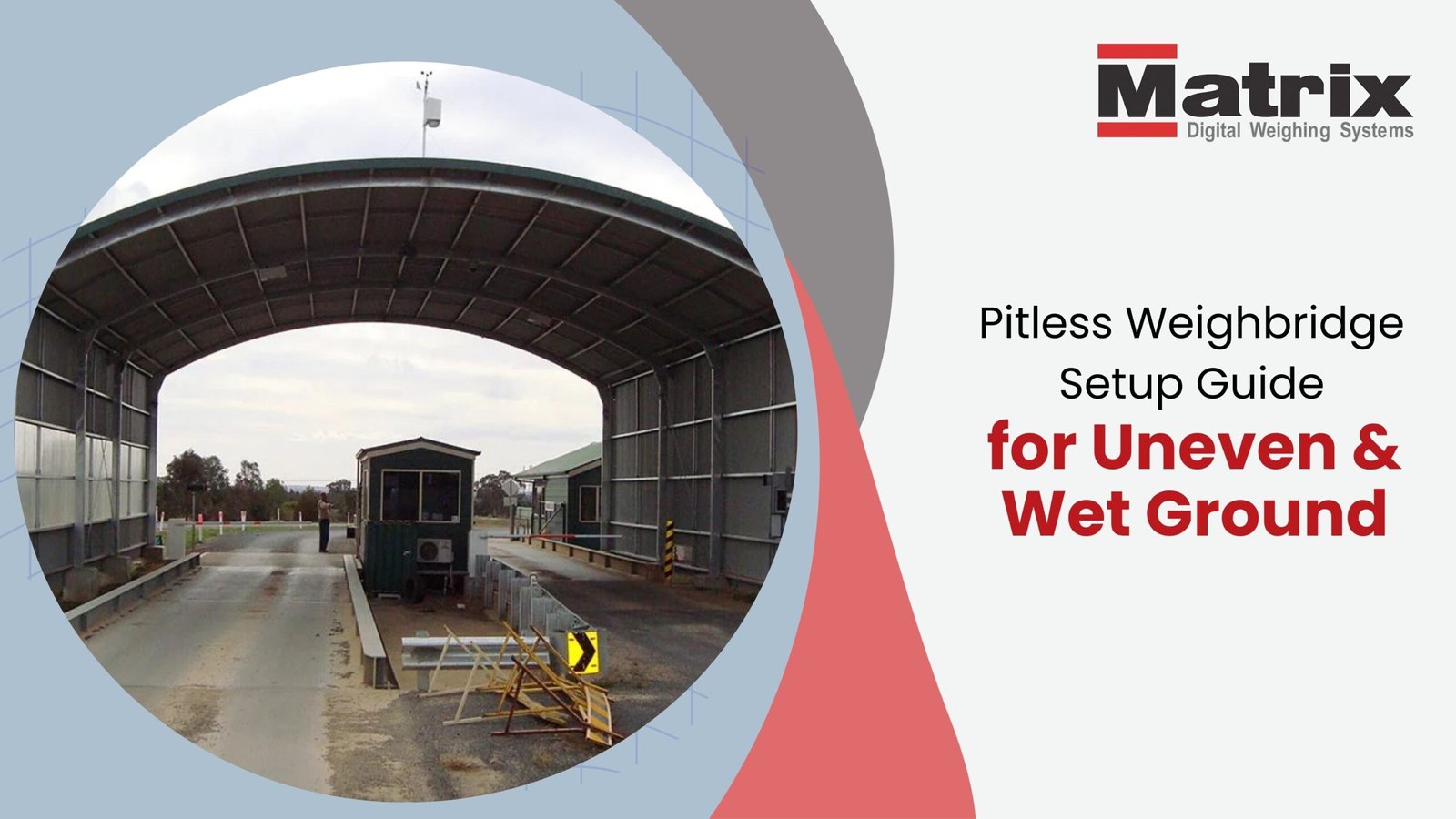

Installing weighbridges on uneven or waterlogged terrain typically means expensive soil stabilization, extended drainage systems, and uncertain foundation performance. Many buyers assume difficult ground conditions require […]

December 4, 2025

Introduction Your bulk logistics operation loses money every time a truck waits more than five minutes at the weighbridge. Manual weighing creates bottlenecks, transcription errors inflate […]

December 4, 2025

Traditional weighbridge installations lock you into permanent configurations that can’t adapt when operations change. Expanding capacity, relocating to new sites, or adjusting platform length requires starting […]

November 21, 2025

The movement of goods via truck transport is the lifeline of modern commerce. For logistics companies, highway authorities, and fleet operators, accurate and efficient vehicle weighing is essential […]

November 20, 2025

Most weighbridge failures stem from neglected maintenance rather than equipment defects. A weighbridge operating without regular cleaning and calibration drifts in accuracy by 2-5% within six […]

November 19, 2025

Introduction A poorly installed pitless weighbridge costs you thousands in repairs, recalibration, and operational downtime within the first year. Installation errors create cascading failures—foundation settling shifts […]