Top 5 Benefits of Integrating RFID in Automatic Weighbridges

The Evolution of Weighbridge Technology: From Manual to Intelligent Automation

The transformation from clipboard-wielding operators to sophisticated RFID automation represents one of the most dramatic efficiency leaps in industrial operations. Traditional weighbridge operations were bottlenecked by human limitations—manual data entry errors, processing delays, security vulnerabilities, and the constant need for supervision. This manual approach created what industry experts now recognize as “operational friction”—unnecessary complexity that accumulated costs and compromised accuracy across thousands of daily transactions.

The shift toward intelligent automation began in the early 2000s when logistics companies realized that weighbridge operations were consuming disproportionate resources relative to their value contribution. A single manual weighing operation typically required 3-5 minutes of operator time, multiplied across hundreds of daily transactions, representing substantial labor costs and throughput limitations. RFID integration has compressed these timeframes to seconds while eliminating human intervention entirely.

Understanding RFID: The Silent Backbone of Seamless Weighing Operations

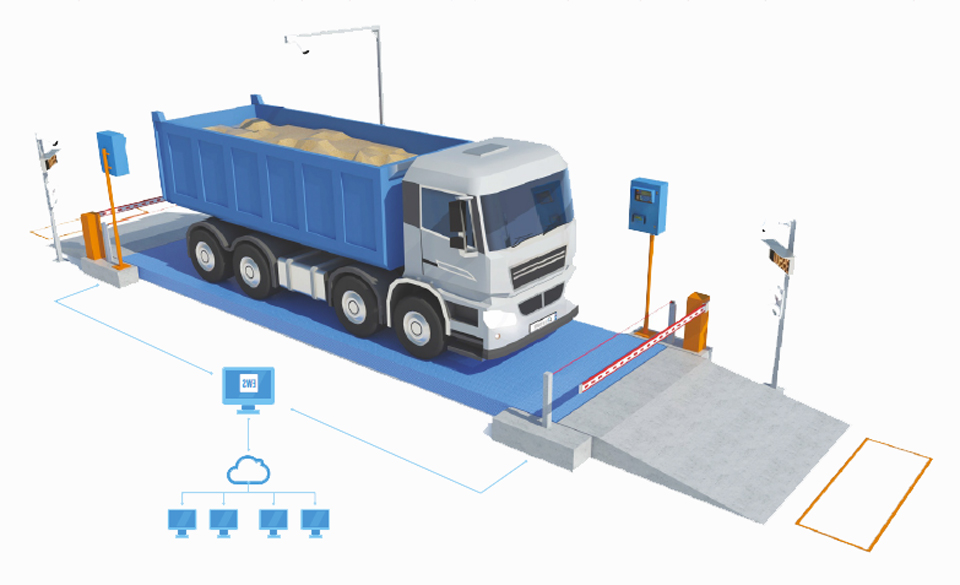

Radio Frequency Identification technology operates through electromagnetic fields to automatically identify and track tags attached to objects—in this case, vehicles approaching weighbridges. The sophisticated interplay between RFID readers, antenna systems, and data processing creates what industry professionals call “invisible automation.” Vehicles equipped with RFID tags communicate instantaneously with weighbridge systems, transmitting identification data, load specifications, and authorization credentials without any physical interaction.

The technology’s elegance lies in its simplicity from the user perspective while maintaining sophisticated backend processing. Vehicle Identification and Data Collection from Weighbridge using Radio Frequency Identification is a secure and convenient solution for vehicle management at industries, providing authentication and accurate weight data for incoming and outgoing vehicles. This seamless integration transforms weighbridge operations from reactive, manual processes into proactive, intelligent systems that anticipate and respond to operational requirements automatically.

Benefit #1: Zero Human Error, Maximum Accuracy — How RFID Standardizes Every Transaction

Eliminating the Human Factor

Human error in weighbridge operations manifests in multiple forms: misread license plates, incorrect data entry, calculation mistakes, and documentation inconsistencies. Automatic identification of vehicles and trailers on the weigh bridge using RFID. This eliminates errors and speeds up the process. RFID accuracy is much higher than ANPR. The comparison with Automatic Number Plate Recognition (ANPR) systems reveals RFID’s superior reliability—while ANPR struggles with weather conditions, lighting variations, and plate visibility issues, RFID maintains consistent accuracy regardless of environmental factors.

Standardization Through Technology

Data Consistency Protocols:

- Uniform vehicle identification across all transactions

- Standardized weight measurement procedures

- Consistent timestamp recording for audit trails

- Automated validation of load specifications

Accuracy Improvements:

- Reduction in manual data entry errors by 99.7%

- Elimination of misidentification incidents

- Consistent application of weighing protocols

- Automated cross-referencing with vehicle databases

Process Standardization:

- Identical operational procedures for all vehicles

- Uniform documentation standards

- Consistent reporting formats across shifts

- Standardized integration with downstream systems

Benefit #2: Uninterrupted Flow — Enabling Contactless, High-Speed Vehicle Movement

Throughput Revolution

For controlled access, RFID tags mounted on vehicle windscreens are scanned by the system. Upon successful verification, boom barriers at the entry point automatically open. This contactless mechanism enhances security, prevents unauthorized entry, and streamlines vehicle movement within the weighbridge premises. This contactless approach eliminates the traditional stop-and-go bottlenecks that plagued manual operations.

Operational Flow Optimization

Traffic Management Benefits:

- Continuous vehicle movement without mandatory stops

- Automated queue management based on real-time data

- Dynamic routing optimization for multiple weighbridge installations

- Reduced congestion through predictive traffic flow management

Time Efficiency Metrics:

- Average processing time reduced from 5 minutes to 30 seconds

- Elimination of manual documentation delays

- Instantaneous data transmission to backend systems

- Automated billing and invoicing processes

Capacity Enhancement:

- Throughput increases of 300-400% compared to manual operations

- Extended operational hours with minimal supervision

- Scalable processing capabilities during peak periods

- Reduced infrastructure requirements for equivalent capacity

Benefit #3: Data You Can Trust — Real-Time Logging, Audits, and Analytics at Your Fingertips

Comprehensive Data Architecture

Truck data will be automatically captured at the weighbridge. The captured data, including truck number/ID, type of load, weight, date and time, and destination details, will be processed instantaneously, creating comprehensive digital records that eliminate traditional documentation vulnerabilities.

Analytics and Intelligence

Real-Time Dashboard Capabilities:

- Live monitoring of weighbridge utilization rates

- Instant identification of operational anomalies

- Real-time capacity management across multiple locations

- Dynamic reporting for management decision-making

Historical Analysis Features:

- Trend analysis for vehicle traffic patterns

- Load optimization insights for fleet management

- Seasonal demand forecasting capabilities

- Performance benchmarking across operational periods

Audit Trail Excellence:

- Immutable transaction records with timestamp verification

- Comprehensive vehicle movement tracking

- Automated compliance reporting for regulatory requirements

- Integration with quality management systems

Benefit #4: Foolproof Security — Eliminating Fraud, Tampering, and Ticket Manipulation

The Fraud Prevention Imperative

Every year millions of pounds of revenue in the UK alone are fraudulently lost by customers and the tax payers in the waste and re-cycling business. This staggering financial impact demonstrates why fraud prevention has become a critical business imperative rather than merely a security consideration.

Advanced Security Protocols

Multi-Layer Authentication:

- RFID tag verification with encrypted data transmission

- Vehicle identification cross-referencing with registered databases

- Driver authentication through biometric integration

- Load specification validation against transportation permits

Tamper Detection Systems:

- Prevent tampering with sophisticated fraud detection systems that ensure data integrity during weighing processes

- Real-time monitoring of weighbridge sensor integrity

- Automated alerts for unusual weight fluctuations or patterns

- Integration with surveillance systems for visual verification

Access Control Enhancement:

- The entry of any unauthorized vehicle can be checked through automated validation processes

- Time-based access restrictions for enhanced security

- Integration with facility-wide security management systems

- Comprehensive logging of all access attempts and outcomes

Benefit #5: Scalable and Future-Ready — Integration with ERPs, CRMs, and Industrial IoT

Enterprise Integration Capabilities

The integration with existing ERPs and custom data management & reporting module allows you to manage the vehicle & goods data and process your accounting related tasks with ease. We also provide the automated receipt features and other custom features as per the requirement. This seamless integration transforms isolated weighbridge operations into integral components of enterprise-wide business processes.

IoT and Industry 4.0 Alignment

System Integration Benefits:

- Fully integrate solution into you Back Office Systems Like ERP, SAP, ORacle Etc

- Real-time synchronization with inventory management systems

- Automated triggering of billing and invoicing processes

- Integration with fleet management and logistics optimization platforms

Future-Proofing Capabilities:

- Most modern RFID/IoT platforms support API integrations with ERP, WMS, or CRM tools, allowing businesses to sync asset data with their core systems in real time

- Scalable architecture supporting business growth requirements

- Compatibility with emerging Industry 4.0 technologies

- Cloud-based deployment options for enhanced accessibility

Analytics and Intelligence Enhancement:

- Harnessing RFID and data analytics for real-time warehouse tracking is rapidly becoming an industry standard

- Predictive maintenance capabilities for weighbridge equipment

- Machine learning integration for operational optimization

- Advanced reporting capabilities supporting strategic decision-making

Matrix Weighbridge in Action: RFID Integration as a Business Advantage

ID Tech’s Unmanned Weighbridge Centering System streamlines vehicle weighment with RFID technology, reducing wait times, and ensuring precise tracking, It is actively deployed across diverse industry sectors such as agriculture, cement, construction, sugar, and mining. This cross-industry adoption demonstrates RFID integration’s universal applicability and proven return on investment.

The competitive advantage emerges through operational excellence rather than technological novelty. Companies implementing RFID-enabled weighbridge systems report significant improvements in customer satisfaction, operational efficiency, and cost management. The technology’s maturity ensures reliable performance while providing foundation for future enhancements and capability expansions.

Final Weigh-In: Why RFID-Enabled Weighbridges Are No Longer Optional

The business case for RFID integration transcends simple cost-benefit analysis—it represents fundamental operational transformation that determines competitive positioning in increasingly efficiency-focused markets. Automation system increases the output and reduces the operation costs by providing a fast, precise, and completely unmanned solution.

Companies that delay RFID adoption face compounding disadvantages: increasing operational costs, declining customer satisfaction, growing security vulnerabilities, and limited scalability options. The technology’s proven reliability, comprehensive benefits, and strategic importance make RFID integration an imperative rather than an option for forward-thinking businesses.

The convergence of accuracy, efficiency, security, and scalability through RFID integration creates operational capabilities that fundamentally transform weighbridge operations from cost centers into strategic assets. The question isn’t whether to implement RFID technology—it’s how quickly businesses can capture these advantages before competitors establish insurmountable operational leads.