Ensure Vehicle Proper Position

Not require managing vehicle position, its auto manage by system.

System auto control weighbridge traffic.

Restrict unauthorized vehicle weight on weighbridge.

CCTV Camera Integration

As complete information is scanned through PLC Controller & CCTV (Camera) Software which reduces the operation cycle and prevents the manual entry errors.

The system makes the weighment process highly secure by allowing integration with IP cameras, and traffic lights for capturing images during the weighment, managing vehicle traffic, vehicle queue management and carrying out safe operation. The system further integrates with ERP systems like SAP and Tally to remove errors due to manual entries.

Traffic Signal (Signal Light)

We provide Best Quality LED Traffic light With Green Color, Red Color. in 12 Volt DC, 24 volt DC, 230 AC…. With Various Dia Like 100 mm, 200 mm, 300 mm….. Provide Customize LED Traffic lights With Customize Light with Various color.

Automatic Boom Barriers offer efficient security at exit and entry points of factories, office complexes, condominiums, parking lots, toll plazas, Truck Scale Automation or any roadway entry where medium to heavy traffic is expected. The boom barrier is aesthetically designed with sleek and modern looks.

Key Benefits

Camera for Vehicle Photo Capturing

Remote Display (Jumbo LED Display)

Traffic Light (Signal Light)

Boom Gate (Barriers)

Control Panel with EWS Software

Loop Detector

Vehicle Positioning Sensor

Camera for Cargo Space

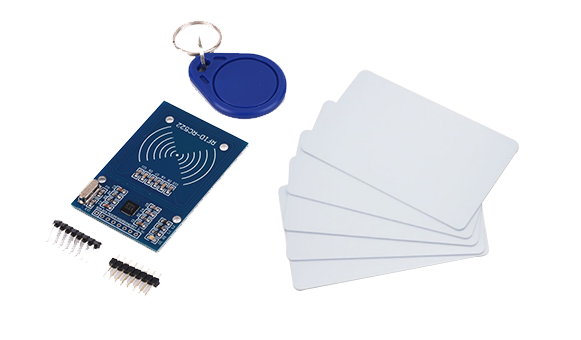

RF Tag System

Non-contacting RF tags, which can be supplied in a variety of shapes such as key fob, credit card, etc. May be specified as an alternative to Data keys. These tags hold a single and unique identifying code on them that cannot be changed but is used to look up full details held on the computer. These would normally comprise registration number, stored tare weight (optional), operator name and address and any other data permanently associated with that vehicle.

The driver holds the tag against the face of the reader, which may be in the weigh cabin or outside on a pole so that it can be accessed without leaving the cab. Everything else is then automatic. If the system is fitted with a touch screen, the driver can be selected, such as vehicle allocated to him, the material carried, etc.

All on drop-down lists. On returning to the weighbridge for the second weighing, the driver again holds the tag against the reader and the system recognizes that it has details of the first weighing, so it knows that this must be a second weighing. The difference between the first and second weights is logged as the net weight and the date, time and consecutive running number is also recorded as described below in the computer section.

Salient Features

Allows data from remote weighbridge locations to sync with central server.

Suitable where network connectivity is not very reliable

The sync server allows easy integration with SAP and other ERP systems.

Records recall based on vehicle number as well as weigh slip number

Ability to send SMS or Emails from remote weighbridges as well as central server.

Ability to push configuration including data fields, ticket settings, code and values form central server to weighbridge PCs.

Connect upto 4 Cameras at each weighbridge

Supports IP Cameras

Configurable data fields and validations.

Data backup and restore.

SMS alerts on weighment. Supports both SMS gateways as well as GSM dongles.

Email alerts on weighment. Images are also sent in email.

Vehicle registration to store tare weight.

Highly configurable ticket settings with support for pre-printed stationery.

Supports dot-matrix printers, graphics printers. Images can be printed using graphics printer.

Powerful reporting module.

Excel export of weighment data.

Truck Scale RFID System

The company Software specializes in the development of weighing systems, combined with the long-range RFID tags. In the system, the RFID tags are installed in the vehicles, e.g. on the containers. The said tag can contain various data about the container, such as container weight, its owner data, etc. When the vehicle enters the weighbridge, the information saved on the tag is identified by the system and automatically sent to the weighing program.

Automatic Boom Barriers offer efficient security at exit and entry points of factories, office complexes, condominiums, parking lots, toll plazas, Truck Scale Automation or any roadway entry where medium to heavy traffic is expected. The boom barrier is aesthetically designed with sleek and modern looks.

Key Benefits

Vehicle Positioning IR Sensor for Vehicle Alignment.

CCTV Camera & Photo Capturing of Number Plate Reorganization

Auto E-Mail Data Transfer Facility by E-Mail (Ticket with Truck Photo’s)

User Password Based Login ID

Instruction announce with loud speaker

Integrate with SAP, Oracle, ERP

Camera Mounting Pole

Photo sensor based system

Traffic Light for safe operations to indicate the status and data to truck Driver

PLC Based Controller (Built In Indicator inside the Controller)

Ethernet Port (LAN port) for server connectivity.

Ethernet Port (LAN port) for server connectivity.